Our Pressure Relief Valve is specifically designed for safeguarding powder silos. It automatically regulates and releases excessive internal pressure, preventing potential hazards such as rupture and leakage, ensuring safe and stable storage powder.

Item No :

ZT-81085Warranty :

1 YEARMain Materials :

Carbon SteelKey Selling Points :

PneumaticCondition :

NewSilo Top Pressure Relief Valve - Safety system for Silos

Quick Details:

| Applicable Industries | Powder silo, cement silo, sand silo |

| Usage | Pressure relief safety valve |

| Dimension(L*W*H) | 370*400mm |

| Warranty of Core Components | 1 Year |

| Connection | Clamp with rubber sealing |

| Body Material | Carbon Steel |

| Certificate | ISO 9001 |

| Function | Waterproof |

| Color | Customizable |

| Packing | carton case or wooden case |

Pressure Relief Valves serve as a critical safety measure for steel silos when abnormal pressure conditions pose a risk to the structure's integrity. These valves are designed to respond immediately to sudden spikes or drops in pressure within the silo, ensuring that the system remains stable and secure. While it's best if a Pressure Relief Valve never has to be activated, it's essential that it performs efficiently and reliably when called upon. This means that the valve should be well-maintained and tested regularly to guarantee its functionality in the event of an emergency. The valve's design should also be robust enough to handle the specific pressure ranges and conditions that the silo might encounter, providing a dependable safeguard against potential structural damage.

Usage Scenario of Pressure Relief Valves

Pressure safety valves are typically installed at the top of metal silos. The silo's roof plate is designed with appropriately sized holes to securely mount the pressure safety valves. These valves are an essential component of the silo's pressure management system, allowing excess pressure to be released when it reaches a certain threshold. The positioning of the valves at the top of the silo ensures that any pressure buildup is effectively managed, preventing potential damage to the silo structure. The holes in the roof plate are carefully sized to accommodate the valves, ensuring a snug fit that maintains the integrity of the silo's design while allowing the valves to function properly. This installation process is crucial for maintaining the safety and efficiency of the silo's operation.

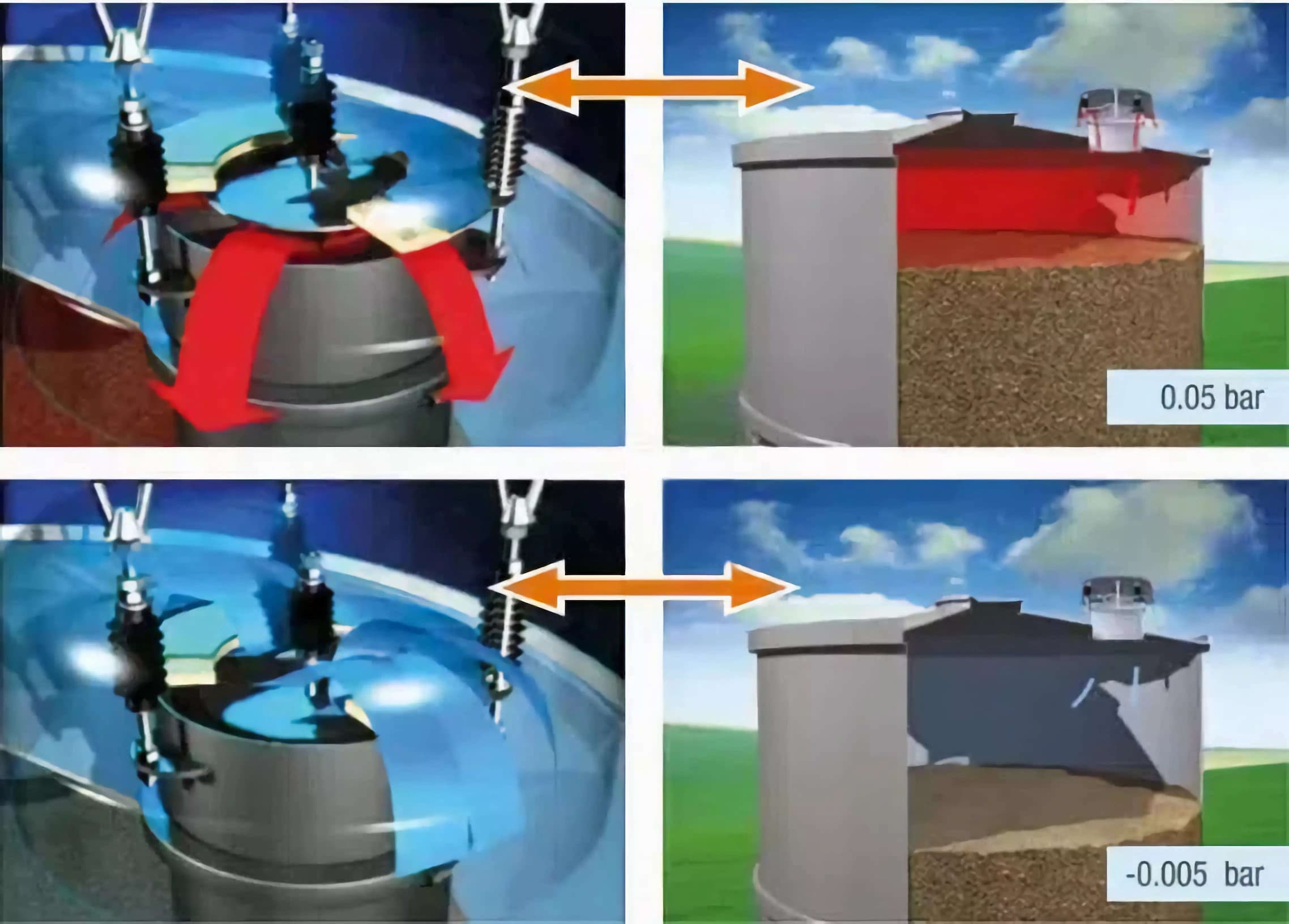

Working Principle of Pressure Relief Valves

When the pressure inside the metal silo stays within the set limits, helical springs ensure that the valve lids remain shut. The three external spring rods maintain a tight seal on the outer ring-shaped lid, provided that the internal pressure doesn't surpass the spring's resistance. If the pressure surpasses the preset threshold, the lid is forced open, allowing pressure to be released. The smaller lid, which is positioned beneath the central circular opening of the larger lid, is secured in place by a single spring rod and is pressed against the outer lid by the normal air pressure within the silo. During instances of suction pressure, the spring compresses, enabling the lid to lower. Fresh air entering the silo from the outside helps to quickly reestablish pressure equilibrium and pushes the central lid back into its "closed" position.

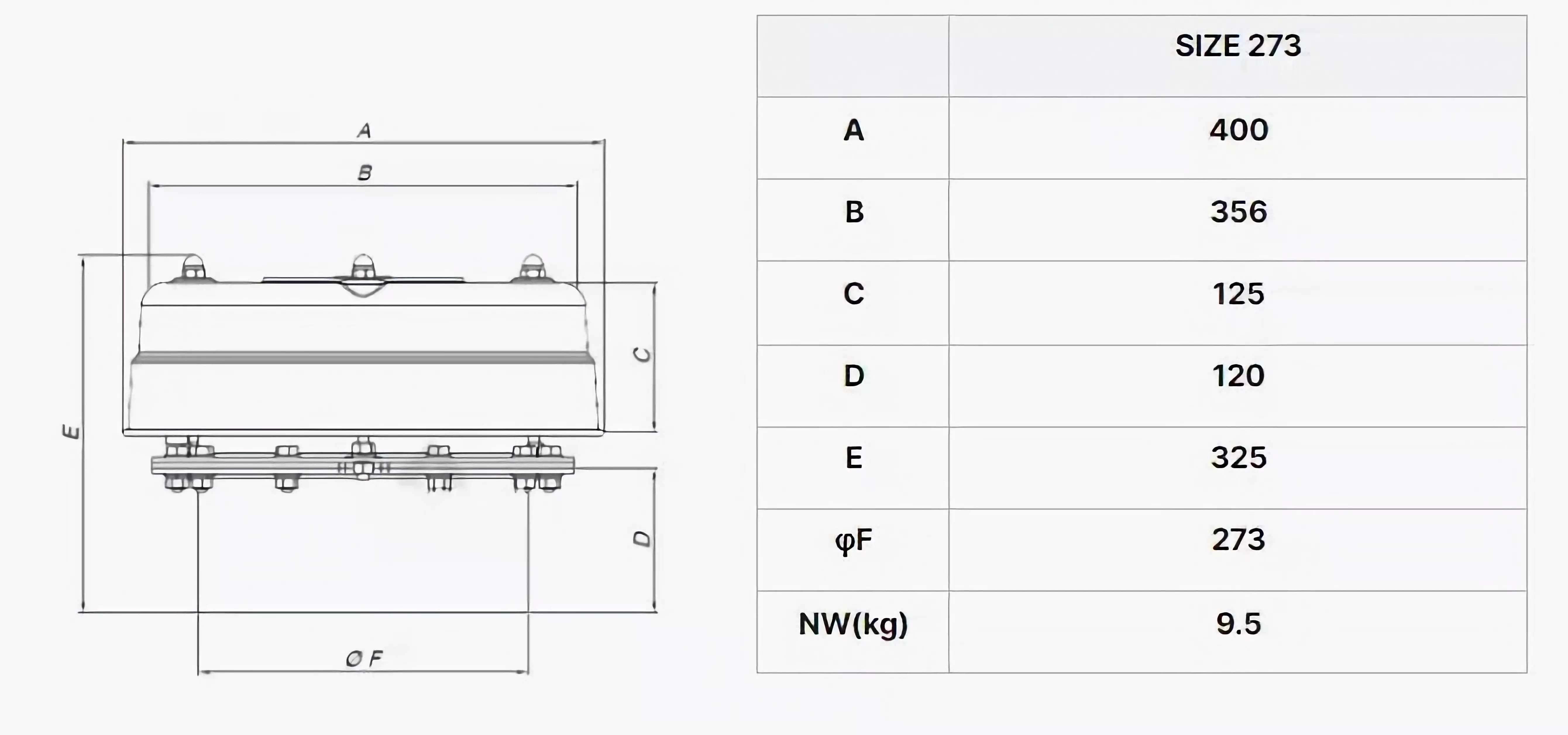

Product Parameter

Standard-sized pressure relief valves are suitable for the majority of cement or sand silos, providing a reliable means of maintaining safe operating pressures within these storage facilities.

Packaging and Transportation for Pressure Relief Valves

Pressure safety valves are generally packaged in cardboard boxes or wooden crates before they leave the factory for transportation. This method of packaging is crucial as it provides effective protection against potential damage that could occur during transit .

FAQ

Q. How can we ensure that our quality is consistently high?

A. Always prepare a pre-production sample for review before proceeding with mass production, and always conduct a final inspection before shipping the goods.

Q. what can you buy from us?

A. Arch breaker device, butterfly valve, dust filter, safety valves, level indicator and screw conveyor.

Q. How is the delivery status? I need the items urgently.

A. For sample orders, delivery within 3 to 7 days will not be an issue. And for regular orders, we commit to a 15-day delivery promise.

Q. What is the warranty period for your products?

A. We provide a one-year warranty for our customers.

Q. Could you please inform me about the packaging standards?

A. Our five-layer corrugated cardboard boxes are designed to withstand the pressure of a person standing on them, so you can have full confidence in our packaging. We reinforce our cartons with four layers of protection, ensuring that our goods are securely packaged according to international standards, which guarantees their safety during transportation.

Q. Would you be willing to use our logo?

A. If you require a substantial quantity, we have absolutely no problem accommodating an OEM order.