100 Ton Welding Steel Mobile Horizontal Fly Ash Cement Silo Tank With Screw Conveyor

Horizontal cement silo tank is widely used in cement, chemical, sand, flyash, mineral lime powder, grain processing, pharmaceutical and other industries to store and supply various powder or granular materials, ensuring that the quality and condition of the materials remain stable during storage.

Item No :

ZT-81021Order(MOQ) :

1 SetWarranty :

2 YearsMain Materials :

Steel Q235BCondition :

NewLeading Time :

25-35 days50 ton to 100 ton small horizontal container mobile cement storage silo for bulk cement, sand and other powders

Quick Details:

Applicable Industries: Construction works, Manufacturing Plant, Energy & Mining, Other

Applicable powder: Fly ash, cement, mineral lime powder, sand, chemical, grain, pellet, concrete and so on

Key Advantages: Greatly reduce compaction and caking, Excellent sealing performance

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Key Words: Horizontal Cement Silo, Steel Silo, Mobile Silo, Storage Silo, Silo Tank, Portable Silo

After-sales service: Video Technical Support

Material: Mild steel-Q235, Grade 250 (AUS), A283 (USA).

Core Components: PLC, Engine, Gearbox, Motor, Gear

Dimension(L*W*H): 12192*2438*5182

Volume: 110 m³/144 tons

Capacity: 45 t/h (Customized)

Air Compressor: 1 unit

Vibrator: 20 units

Plate Thickness: 5 mm. Thicker plates are customized.

Color: Customized

Function: Powder Storage

Packaging: Exporting Packaging

Horizontal cement silo is widely used in cement, chemical, sand, flyash, mineral lime powder, grain processing, pharmaceutical and other industries to store and supply various powder or granular materials, ensuring that the quality and condition of the materials remain stable during storage.

Advantages:

1. Reduce compaction and caking: The horizontal placement design helps reduce compaction and caking of materials during storage and maintains the fluidity of materials.

2. Excellent sealing performance: Excellent sealing performance can prevent the material from being damp, contaminated or leaking to ensure the quality and safety of the material.

3. Strong adaptability: The capacity and specifications of Horizontal powder silo can be customized according to actual needs to meet the needs of different industries and application scenarios.

PRODUCT PARAMETER OF HORIZONTAL SILOS

|

Volume |

110 m³/144 tons |

|

Size (mm) |

12192*2438*5182 |

|

Steel plate thickness |

5 mm |

|

Air compressor |

1 unit |

|

Vibrator |

20 sets |

|

Upper level sensor |

12 units |

|

Lower level sensor |

12 units |

|

Pressure relief valve |

2 sets |

|

Dust collector |

1 set |

|

Control cabinet |

Fully-automatic control system |

NOTE: Accept customization of horizontal sand silo according customer requirement.

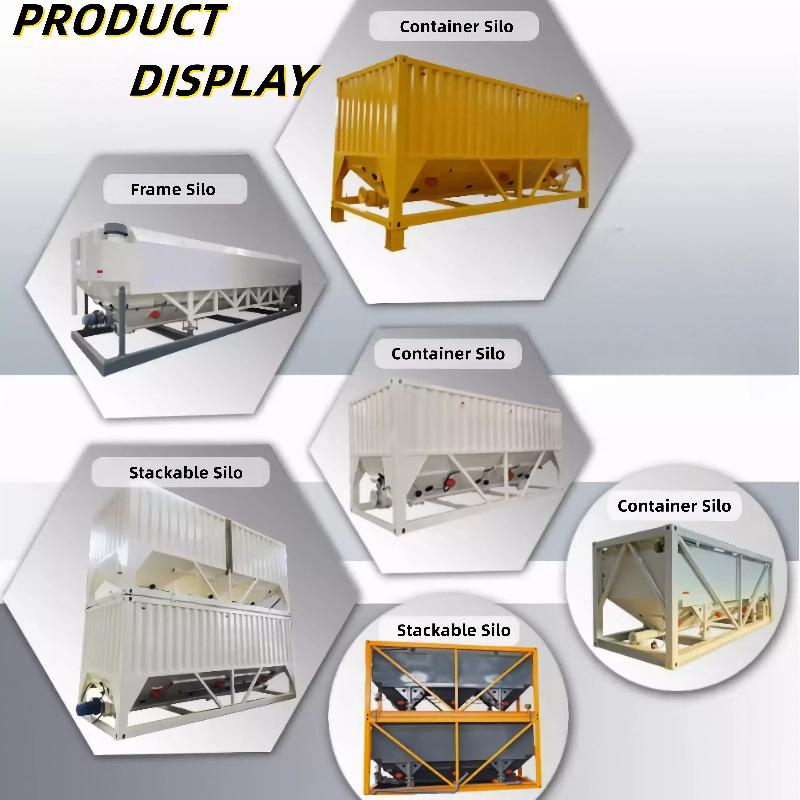

Horizontal powder silos of different shapes

Our factory specializes in the production of horizontal silos of various shapes and configurations, which have excellent loading capacity and can safely and efficiently store a variety of powders used in production, including cement, fly ash, manganese powder and various mineral powders, sand and so on, ensuring a smooth and efficient production process.

FAQ:

1.What kind terms of payment of horizontal cement silos can be accepted?

A: Normally we can work on T/T term or L/C term.

2.What trade terms of farm silo do we accept?

A: Normally we work on EXW, FOB, CFR, CIF, DAP

3.What about the delivery time for silo product?

A: 7-30 days after receiving the deposit.

4.What about the warranty time of silo cement?

A: 24 months after delivery generally.

5.What about the MOQ of silo for cement?

A: MOQ 1 unit