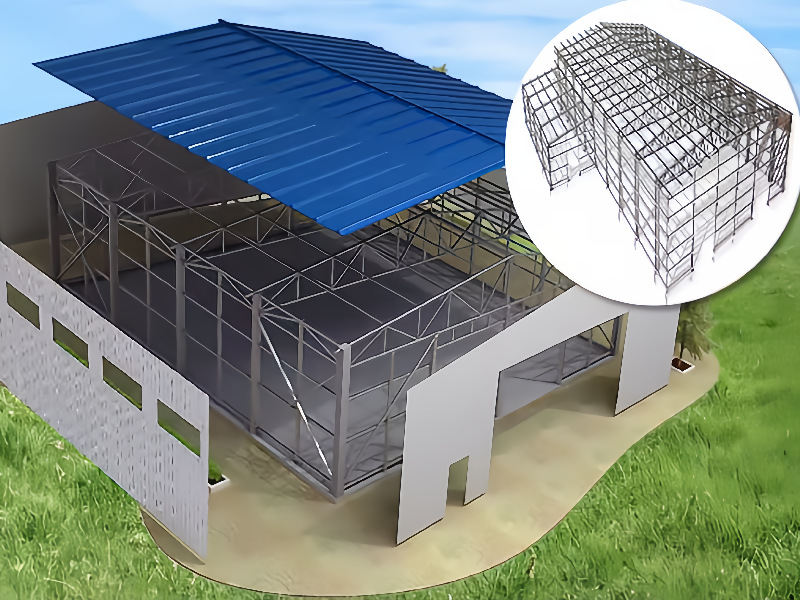

Expertly Crafted Design Solutions for Steel-Structured Warehouse Facilities

Item No :

ZT-81066Order(MOQ) :

1 SetDesign :

ProvideRange of Application :

Warehouse/ WorkshopMain Materials :

Light Steel Q345 Q235Condition :

NewLow cost cheap price prefabricated light steel structure warehouse

Quick Details:

| Applicable: | Warehouse/ Steel workshop/ Hangar/ Garage/ Chicken Shed/ Exhibition Hall/ Car Parking/ Agricultural Storage/ Logistic Centers |

| Key Words: | Steel Metal Frame Structure Warehouse, Commercial Steel Structures Warehouse |

| Process: | Bending, Welding, Decoiling, Cutting, Punching |

| Purling: | C.Z Shape Steel Channel |

| Main frame: | Solid H-shape Steel Beam |

| Tolerance: | ±1% |

| Material: | Q235B/Q345B Low Carbon Steel |

| Window: | Aluminum Alloy Window |

| Surface treatment: | Hot Dip Galvanized |

| Roofing: | Sandwich Panel. Single Steel Sheet |

| Standard: | AiSi/ ASTM |

| Size: | Customized Size\Client's Drawings |

| Machinery Test Report: | Provided |

We offer free steel warehouse structure design drawings for your convenience. Our steel prefabricated buildings system ensures fast and flexible installation, while also being safe and equipped with features such as heat insulation, sound insulation, waterproofing, and fire resistance. With a high price-performance ratio, the convenience of installation significantly reduces both steel structural project duration and costs. Our durable system requires easy maintenance and can last for over 50 years. The perfect design effectively prevents seepage and leakage while meeting national fire safety standards. Moreover, it has a strong bearing capacity that can withstand strong winds, earthquakes, and heavy snow loads.

Our company specializes in a diverse range of steel structure products, including warehouses, workshops, prefabricated garages, greenhouses, high-rise buildings, agricultural structures, and 4S shops. We pride ourselves on offering comprehensive one-stop services that encompass design, production, transportation, and installation guidance. This full approach is customized to satisfy both the specific requirements of our customers and the broader demands of the market, ensuring seamless project execution from concept to completion.

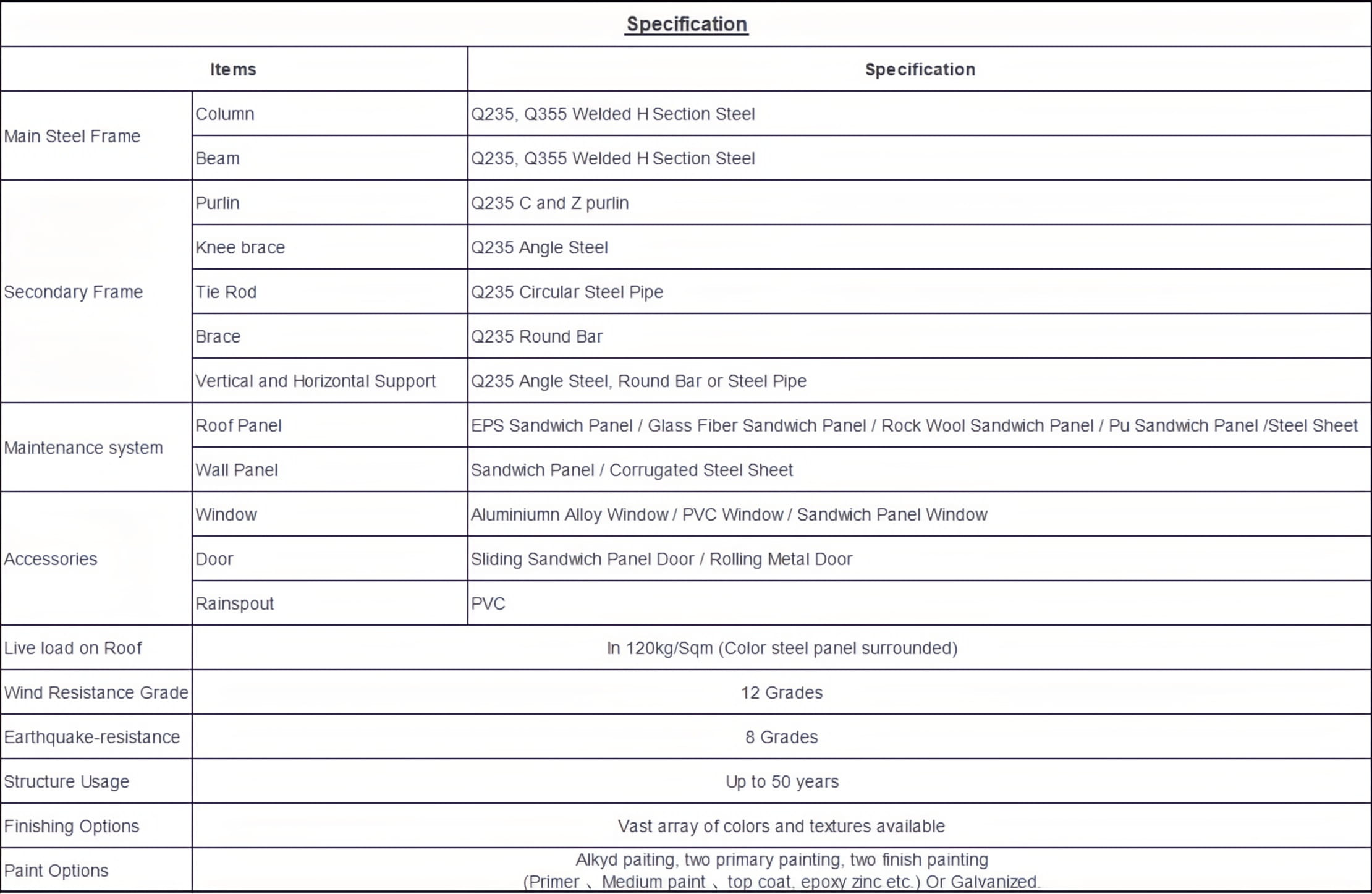

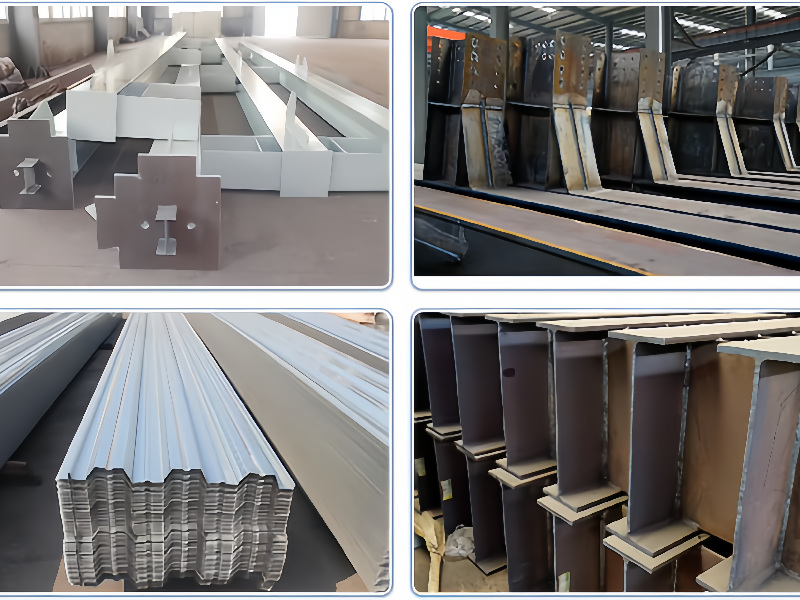

High Quality Raw Materials And Excellent Welding On Steel Structure Warehouse

The selection of high-quality raw materials is important in steel framed structures manufacturing, as it directly influences the integrity, durability, and performance of the final project. High quality steel ensures greater tensile strength and ductility, allowing structures to withstand various loads and stresses without compromising safety. It also plays a key role in resistance to corrosion, which is essential for extending the lifespan of the steel structure warehouse and reducing maintenance costs. Furthermore, the quality of the raw materials impacts the ease of processing, such as cutting, welding, and forming, which in turn affects the precision and efficiency of the construction process.

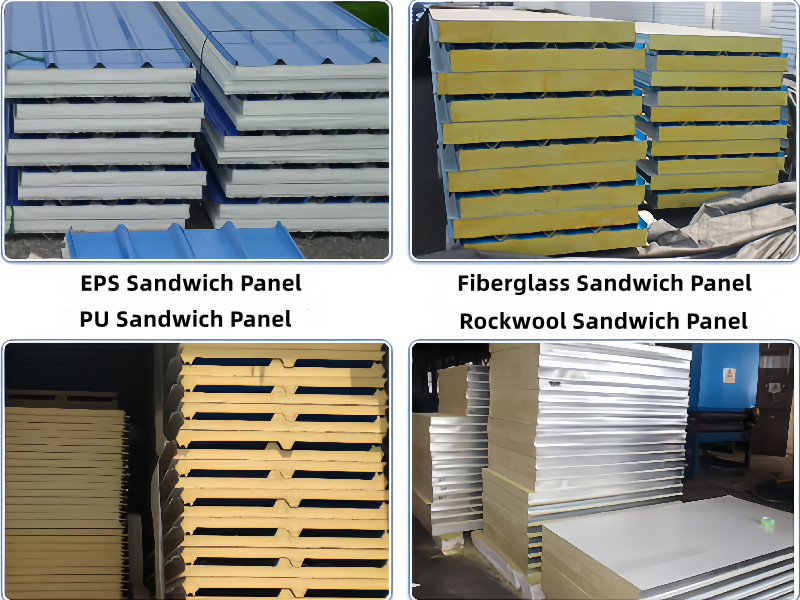

A Variety Of Exterior And Roof Materials For Steel Structure Warehouse Construction

Production and Processing About Steel Warehouse Structure

The production of steel structure warehouse is a process that starts with the careful selection of raw materials, followed by precise cutting and shaping using CAD/CAM technology and with flame cutting machine. Each steel piece is then drilled and punched to facilitate assembly, which is welded and joined by skilled professionals. To ensure long-term use, the surfaces are treated against environmental wear, and the components are assembled into a robust structure. Quality assurance checks are conducted to verify compliance with strict standards.

Packaging And Transportation On Steel Structure

Our Service For Steel Structure Warehouse Construction

Pre-sale Service

We provide a personalized service package that includes supplying technical parameters for related machinery, customizing factory layouts to fit customer space, and preparing formulations based on material costs. We also manufacture special machines to meet unique customer requests and offer expert advice on market trends, machinery operation, processing, materials, and packaging. Additionally, we assist with professional shipping agent recommendations or ship booking services as needed, ensuring a seamless and comprehensive support system for our customers.

After-sale Service

We offer a tailored service package to meet our clients' needs, including supplying allocation charts as per buyer requests, devising space-efficient equipment placement schemes based on the client's plant size, and providing a range of optional basic formulas. An operation manual is provided post-shipment to ensure smooth operation. Our commitment extends to a one-year warranty and lifetime maintenance, along with complimentary quick-wear parts and free training to support our clients throughout the lifecycle of the equipment.