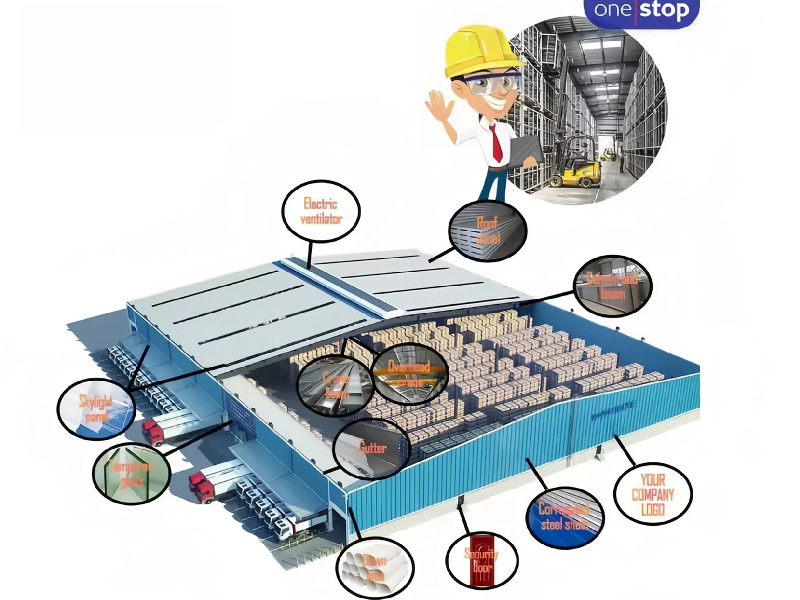

Every component in this steel structure guarantees precision and quality, as it is produced according to a standardized factory procedure. On the construction site, the swift assembly of these prefabricated parts not only significantly reduces the construction period but also minimizes noise and pollution.

Item No :

ZT-81075Range of Application :

Steel Workshop, Steel Structure Warehouse, Steel structure Farm Shed, Steel Structure GarageMain Materials :

Light Steel Q355 Q235Key Selling Points :

Lightweight Steel Structure, Galvanized Steel StructuresCondition :

NewCustomized Prefabricated Steel Structure Building Low Cost Office Factory Workshop Warehouse Steel Structure Building

Quick Details:

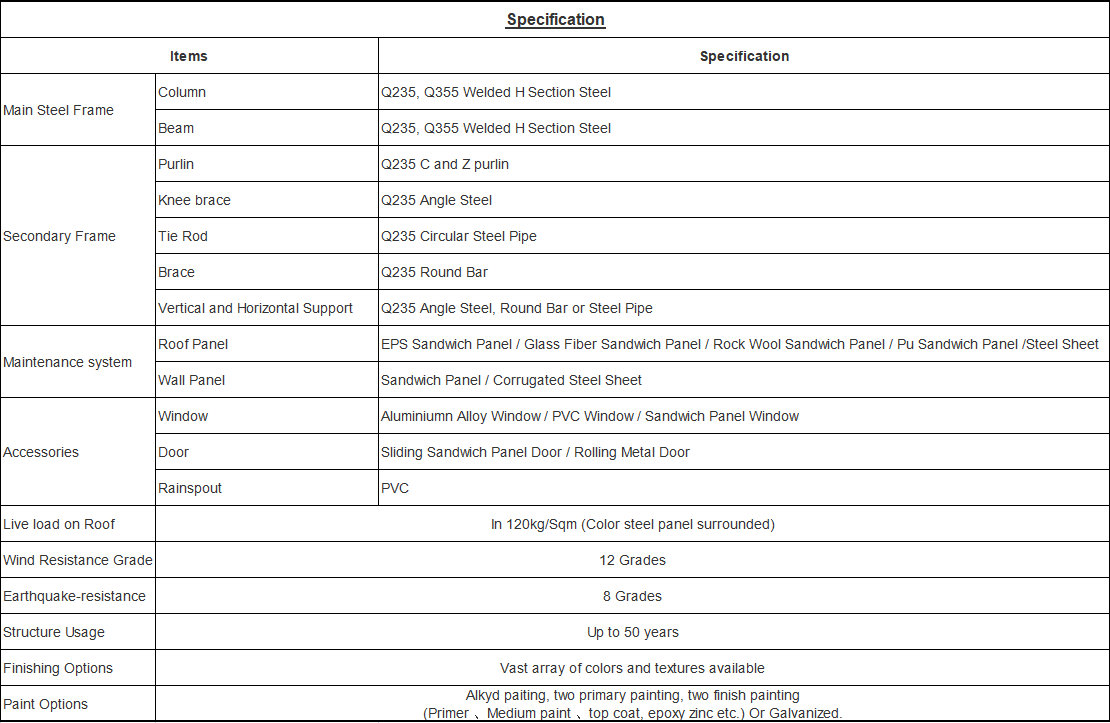

| Structure type | Light Steel Structure |

| Raw Material | Steel Q 235/Q 355 |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Tolerance | ±1% |

| Standard | GB |

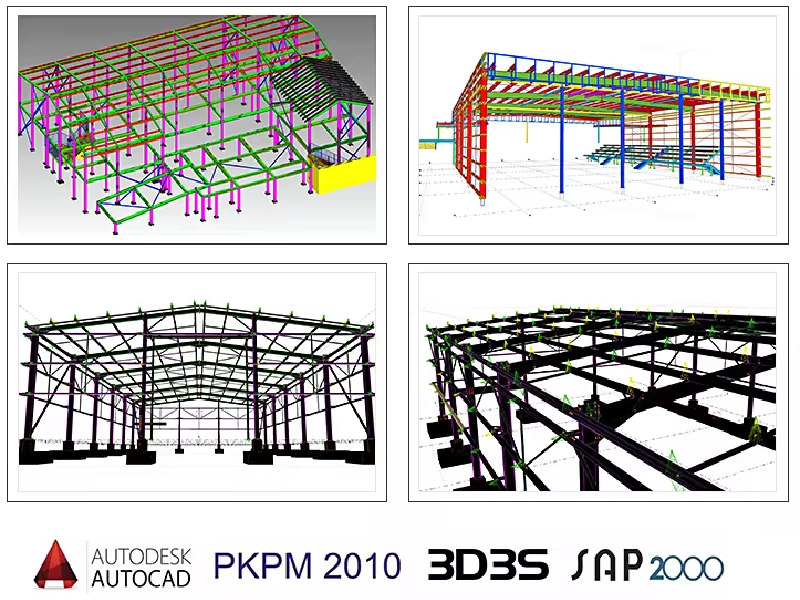

| Drawing Design | SAP2000/ AutoCAD / PKPM / 3D3S/ TEKLA |

| Certificate | CE/ISO 9001 |

| Color | Customized Color |

| Surface Treatment | Painted/ Galvanization |

| Delivery Time | 25-60 days |

| Life Span | 50 Years |

Steel structure buildings prominently distinguish themselves within the construction industry, owing to their myriad of advantages. The highly industrialized manufacturing process underlying steel framed structures guarantees uniform quality control, enabling swift and precise assembly. This, in turn, drastically curtails construction timelines, enhancing project of steel structural building efficiency and reducing overall costs. Moreover, these structures are designed with disassembly in consideration, fostering a circular economy through the promotion of recycling and minimizing environmental footprints.

The confluence of these attributes—lightweight construction, seismic resilience, streamlined production processes, rapid assembly capabilities, and unparalleled sustainability—positions steel structures as the premier choice for modern, efficient, and environmentally conscious construction projects.

With 25 years of dedicated expertise in the steel construction industry, we have honed our professionalism and developed a profound understanding of steel structures, making us a reliable partner in this field.

|

|

To offer an accurate quote for a light steel structure warehouse, key factors must be evaluated. Local site conditions, especially wind speed and snow load in snowy regions, directly affect stability and design. The size and layout of the structure dictate the amount of steel and materials needed. Access to detailed drawings streamlines the estimation process, enabling a more precise quote. By considering these aspects, we produce cost-effective solutions tailored to clients' needs and budgets. Our expertise in the steel structure construction industry ensures that the final product meets stability requirements while optimizing material usage, thereby delivering a high-quality steel structure warehouse within financial constraints.

Packaging and Transportation

We specialize in providing comprehensive protective packaging solutions tailored specifically for steel structures. The steel frames are meticulously loaded into either 40' Open Top (OT) or 40' General Purpose (GP) containers to ensure safe transportation. Meanwhile, the roof and wall panels, along with other ancillary components, are carefully arranged within either 40' High Cube (HQ) or 40' GP containers, taking into account their fragility and the need for optimal space utilization. This meticulous approach to packing and shipping ensures that every aspect of the steel structure arrives at its destination in pristine condition, ready for installation, adhering to the highest standards of the steel construction industry.

FAQ

Q1: How long will it take me to get my product?

A: Delivery time varies from client to client, usually takes 2 weeks to design and confirm according to the drawing of the site and size, the design goes through and 6-8 weeks of delivery (depending on the complexity).

Q2: What are the benefits of steel structure?

A: 1. Durable and long service life.

2. The construction period is shorter than that of concrete and wooden buildings.

3, low cost, reusable.

4, high strength, light weight, with good seismic performance.

5, widely used in multi-purpose buildings.

Q3: Why choose ZHONGTAI?

A: We respect our customers and design and manufacture our products according to their needs. We have more than 10 years of experience in metal construction. We are also a very reputable manufacturer. If you do not have a mature solution, we will patiently answer your needs and help you improve your solution together. We care about your needs and value your business.

Q4: How can I get a quote for this project?

A: If you have the drawings, we can give you the corresponding quotation very soon. If you do not have a design, our engineers will design for you to confirm. And I'll give you a quote.

Q5: Do you provide design services for us?

A: Yes, we can provide complete solution drawings according to your requirements. Use AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (X steel) and other software. We can design complex industrial buildings, such as office buildings, supermarkets, car dealerships, shipping malls, hotels, etc.

Q6: Do you provide samples?

A: Yes, we can provide samples free of charge, but we don't pay for shipping. If the value of your sample is too high, we will also appropriately charge for the sample.

Q7: What are your terms of payment?

A: Letters of credit, T/T and Western Union money transfers.

Q8: How about your quality control?

A: We have our own professional quality control team with rich experience and advanced testing equipment. In addition, we are willing to accept any other third party inspection parts to control.

Q9: Can you provide installation help?

A: We will provide you with detailed instructions, photos and videos. If necessary, we will send professional engineers to guide the construction and some skilled workers to help with the installation. However, visa fees, air tickets, accommodation and salaries will be provided by the buyer.