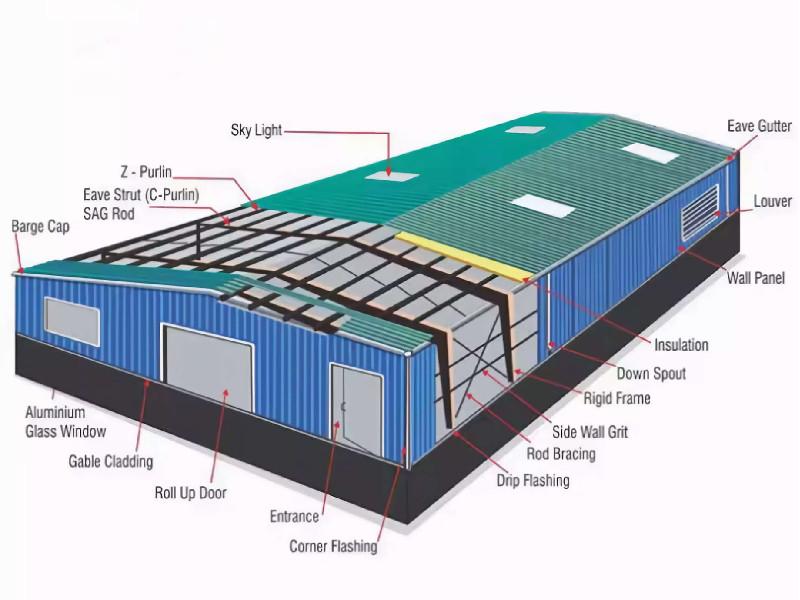

A steel structure workshop is a workshop or factory building that uses steel as the main load-bearing component. The workshop of this structure has been widely used in modern industrial construction because of its unique advantages, such as high strength, light weight, fast construction speed, excellent seismic performance, etc.

Item No :

ZT-81037Range of Application :

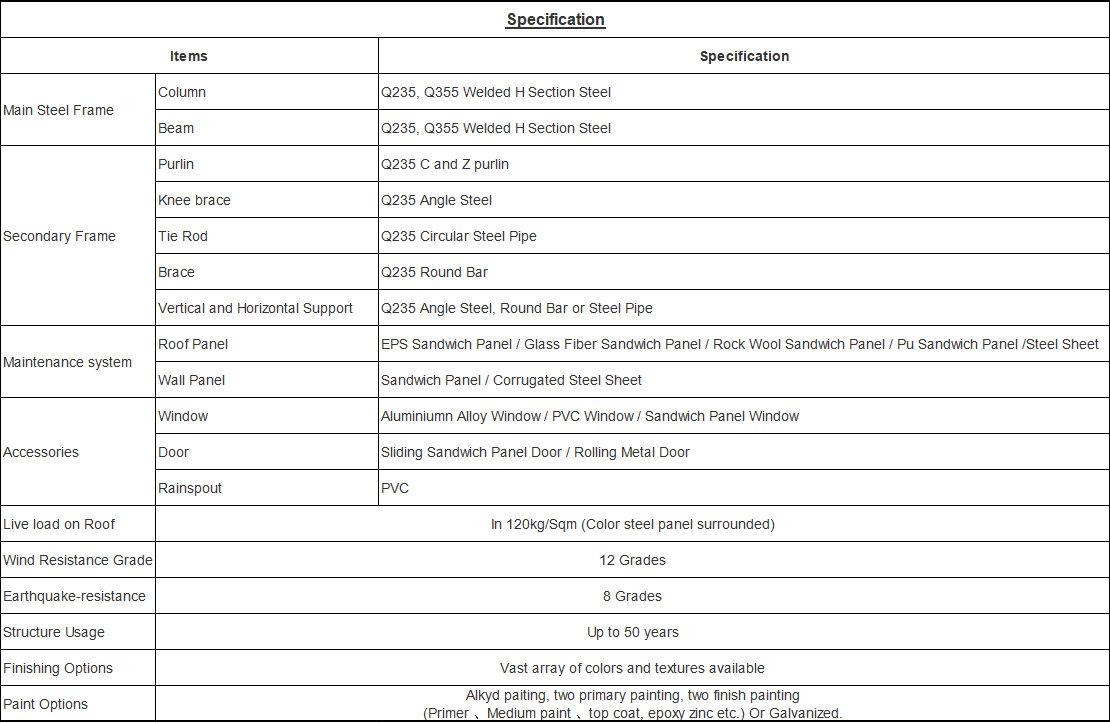

Steel Workshop, Steel Structure Warehouse, Steel structure Farm Shed, Steel Structure GarageMain Materials :

Light Steel Q345 Q235Condition :

NewDesign Drawing :

ProvidePrefabricated 2000sqm Light Steel Structure Metal Workshop

Quick Details:

Applicable: Steel Structure Workshop, Steel Structure Warehouse, Steel Structure Garage, Steel structure farm shed, Steel Structure Livestock Shed, Parking Shed.

Key Words: Steel Metal Frame Structure Workshop, Commercial Steel Structures Workshop

Process: Bending, Welding, Decoiling, Cutting, Punching

Purling: C.Z Shape Steel Channel

Main frame: Solid H-shape Steel Beam

Tolerance: ±1%

Material: Q235B/Q345B Low Carbon Steel

Window: Aluminum Alloy Window

Surface treatment: Hot Dip Galvanized

Roofing: Sandwich Panel. Single Steel Sheet

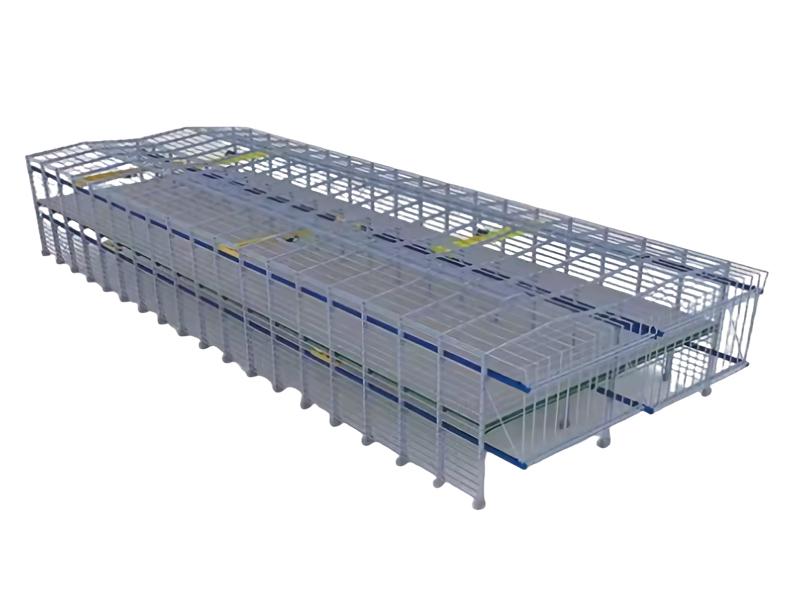

Structure type: Long-span Grid Structure

Standard: AiSi/ ASTM

Size: Customized Size\Client's Drawings

Video outgoing-inspection: Provided

Machinery Test Report: Provided

After-sales service: Video Technical Support

The main load-bearing components of the steel structure workshop include steel columns, steel beams, steel trusses, etc. These components are assembled by welding, bolted connection, etc., to form a stable overall structure. Compared with the traditional concrete structure, the steel structure workshop has higher strength and better durability, and can meet the needs of various industrial production.

In addition, the steel structure workshop also has the advantages of fast construction speed and short construction period. Because the steel can be prefabricated in the factory and then transported to the site for assembly, the construction time is greatly reduced and the construction efficiency is improved. Besides, the steel structure workshop also has good seismic performance and can effectively resist the impact of natural disasters such as earthquakes.

EXCELLENT DESIGN AND MANUFACTURING TEAM

Our company is proud to have a strong design and manufacturing team, they not only have a wealth of professional knowledge and technical background, but also have a deep understanding and enthusiasm for steel structure design and production. This team brings together the elite talents in the industry, they are proficient in various steel structure design principles and skills, according to the needs of customers and the actual situation on the site, tailored to create both safe and stable and economic and practical steel structure design.

|

|

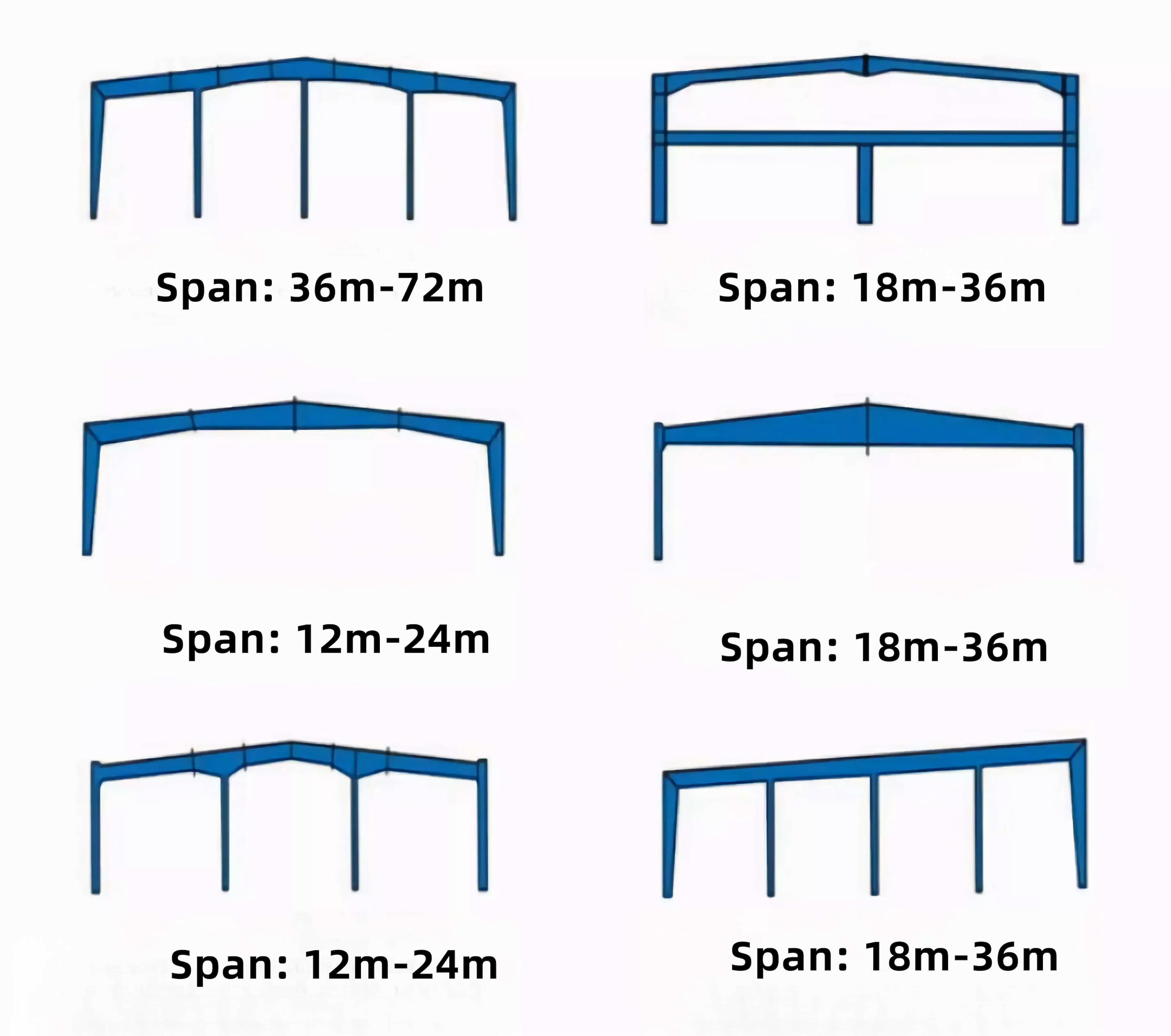

STEEL STRUCTURES OF DIFFERENT DESIGNS

According to the different actual needs of customers, we have designed a variety of shapes of steel structure warehouse/workshop. For example, in places where efficient use of space is required, we will design tall, spacious rectangular warehouses; In areas that require flexible layout and ease of management, we choose to design polygonal or irregular shaped warehouses. These designs not only meet the actual needs of customers, but also ensure the stability and security of the warehouse structure.

HIGH QUALITY RAW MATERIALS AND ACCESSORIES

In the process of steel structure production, we use advanced production technology and technology to ensure that each process meets the quality requirements. From steel cutting, welding to surface treatment, we uphold the attitude of excellence, and strive to make every detail perfect. This production process can not only ensure the stability and safety of the steel structure, but also extend its service life.

PACKAGING& TRANSPORTATION OF STRUCTURE OF MILD STEEL

FAQ:

Q1: What are the benefits of steel construction?

1-Durable and with long lifespan.

2-Short construction period than concrete and wooden building.

3-Low cost and reusable.

4-High strength and light weight, has good seismic performance.

5-Widely used for multi-purpose buildings.

Q2: How can l get the quotation of the project?

lf you have the drawing, we can offer you our quotation accordingly.

lf you have no design, our engineer will design for you to confirm. And then offer you a quotation.

Q3: Do you provide samples?

Yes, we could offer the sample for free but do not pay for the cost of transportation.

Q4: What is your terms of payment?

L/C, T/T, and Western Union.

Q5: How about your quality control?

We have our own professional quality control team with rich experience and advanced inspection equipment.

Q6: Can you provide the installation help?

We will provide detailed instruction photos and videos to you. If it is necessary,we will send professional engineers to do the construction guidance, and some skilled workers to help for installation.