Hot Dipped Galvanized Steel Grating is a steel grating dipped in hot dip galvanizing process with excellent corrosion resistance and strength, widely used in outdoor environments.

Item No :

ZT-81048Order(MOQ) :

100 PiecesRange of Application :

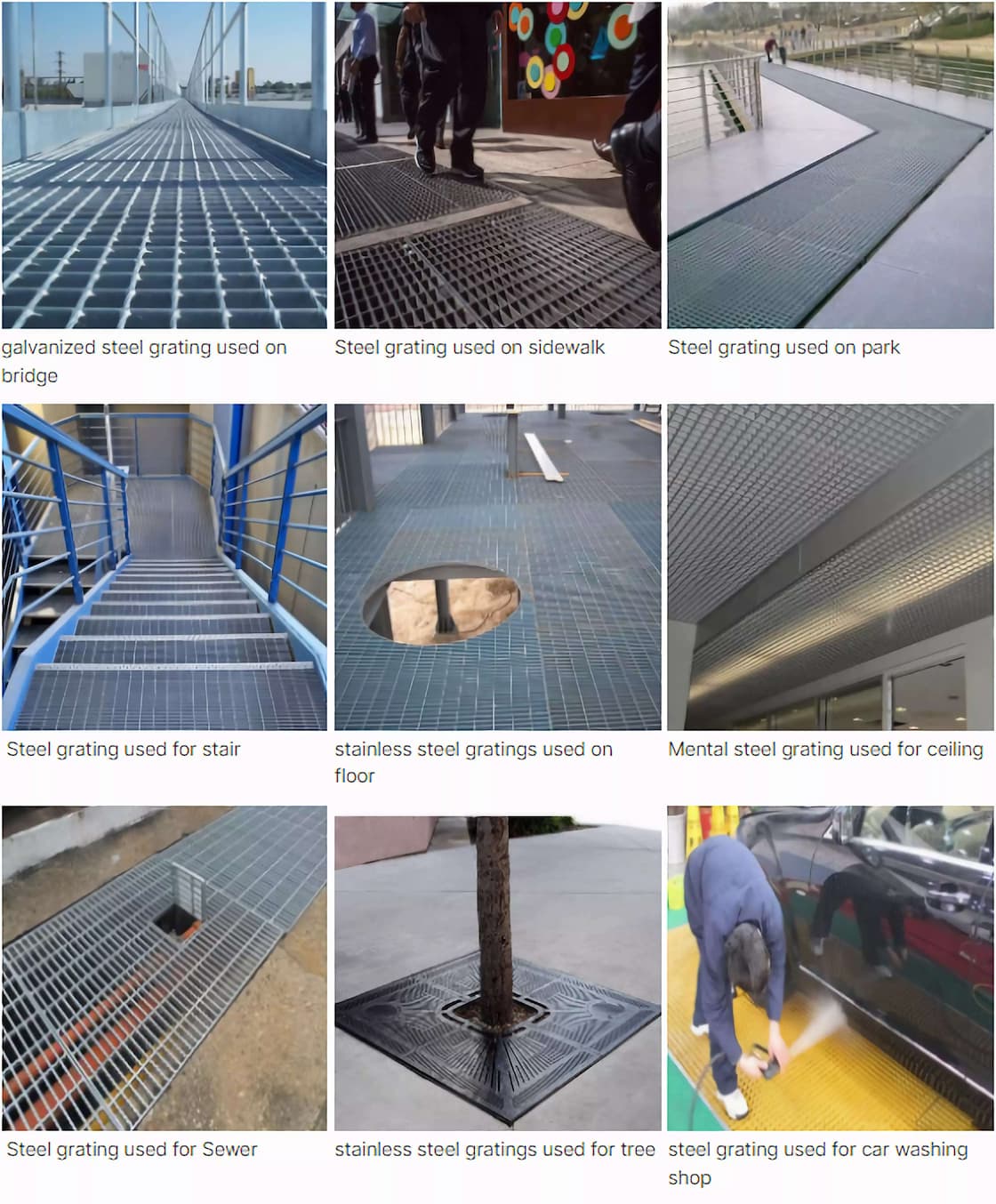

Steel Structure Walkway, Foot Pedal, Drain Cover, IndustryMain Materials :

Carbon Steel/ Stainless SteelKey Selling Points :

Hot Dip GalvanizedCondition :

NewHigh Quality Metal Building Materials Hot Dipped Galvanized Walkway Steel Grating

Quick Details:

Type: Grille plate

Surface Structure: Hot-dip galvanizing, Cold-dip Galvanizing, Spray Paint Polishing

Key Words: Walkway Steel Grating, Metal Drain Grating, Stainless Steel Grating, Heavy Duty Steel Floor Grating

Product material: Mild Carbon Steel, Stainless Steel

Size: Customized

Color: Customized

MOQ: 100 Piece

Product Advantage: Strong Welding Spot, Strong Anti-corrosion & Anti-rust, Beautiful & Practical

Purpose: Chemical Plant, Power Plant, Water Plant, Parking Lot, Construction Field, Platform, Walkway, Ditch Cover, Manhole Cover

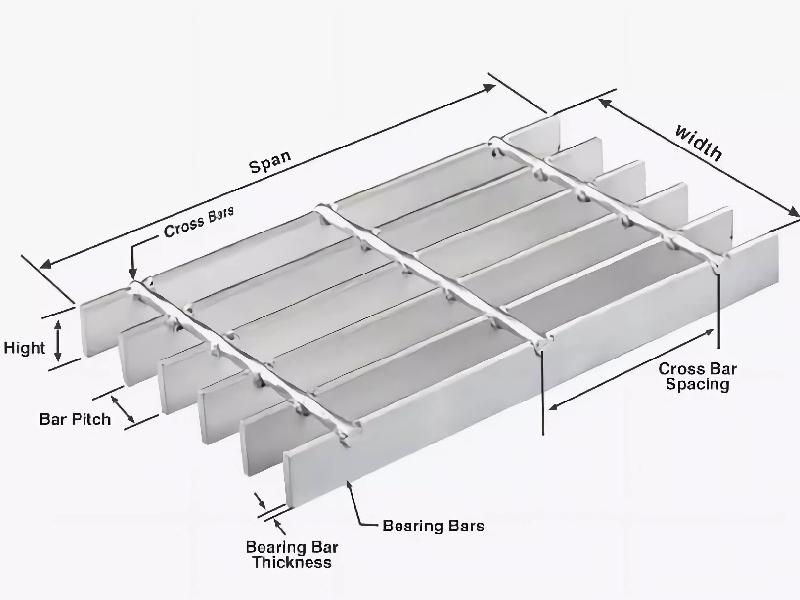

Mild steel grating is crafted through a series of processes involving cutting, incision, opening, and over-locking, using bearing bars and cross bars in a flat-steel weft configuration. These components are welded together on a resistance welder under high-pressure spacing to fulfill customer specifications and yield the desired finished product.

PRODUCT DETAILS OF INDUSTRIAL STEEL GRATING

The superior performance of heavy duty galvanized steel gratings and the application of the mining industry have been well developed, as follows:

1. Heavy duty steel floor grating saves the amount of steel used: The most steel-saving amount under the same load conditions, and correspondingly reduce the material of the support structure.

2.The appearance of modern style: beautiful appearance, design specifications, ventilation and light, giving people a modern and smooth overall feeling.

3. Can greatly reduce investment: save materials, labor, labor, free cleaning and maintenance.

4.The installation time is short, can greatly save the construction period: the product does not need on-site processing, the installation is very fast.

5. The grid structure to prevent accumulation of dirt: no accumulation of rain, ice and dust.

6. Ventilation, lighting, heat, explosion-proof, anti-skid performance.

PACKAGING & TRANSPORTATION OF HEAVY STEEL GRATING

Packaging can be customized using various methods such as packing, boxing, or welding steel brackets, depending on the customer's needs, to guarantee the safety of the cargo during transportation and ensure that the mild steel grating arrives in pristine condition at the hands of the customer.

RELATED APPLICATION SCENARIOS ABOUT GALVANIZED GRATING

FAQ:

Q. How long can be your expanded metal grating survived?

A. As a standard, our products are designed to last for at least 10 years. However, we also can meet to our clients' specific needs by offering products with an extended lifespan of up to 20 years, such as aluminum fences and heavy-duty hot-dip galvanized fences.

Q. What is the payment terms of metal grating?

A. Our factory payment term: T/T by 30% as deposit, 70% as balance before leaving factory.

Q. Can you accept customization?

A. Yes. We also offer customization services. If you require assistance, our design team is readily available to create a design to your specific requirements, including the design aspects.

If you want to know more about our other product, please feel free to contact me! Your kind inquiry is highly appreciated.