CNC machining has significant advantages over manual machining. It can produce very accurate and repeatable parts; It can process parts with complex shapes that cannot be completed by manual processing; The high degree of automation in the processing process improves the production efficiency.

Item No :

ZT-81031Design :

Client's DrawingsVideo Outgoing-inspection :

ProvideRange of Application :

Aerospace/ Equipment/ Machine/ Auto partMain Materials :

Stainless Steel/ Aluminum/ Brass/ Copper/ Steel/ Titanium Alloy/ IronCondition :

NewLarge Size Anodize Metal Aluminum Parts CNC Milling Turning Machining Service with Laser Technology

Quick Details

Applicable: Industrial Equipment, Aerospace, Equipment, Machine, Auto part

Key Words: CNC Machining Works, CNC Custom Machining, CNC Machining Works, CNC Machining Centre

Type: Broaching, Drilling, Etching, Chemical Machining, Laser Machining, Milling, urning, Wire EDM, Rapid Prototyping

Micro Machining or Not: Micro Machining

Materials: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

Process: CNC Machining, Turning, Grinding, Wire-Cutting

Certification: ISO9001:2008

Color: Black, Silver, Blue, Gold (Customized)

Surface Treatment: Silver anodized, Powder Coating, Polishing, Brushed

Deep Processing: Cutting,Milling,Drilling,Punching and Bending

Service: One-Stop Service

Size: Customized Size\Client's Drawings

OEM/ ODM: Accepted

Sample: Provide

CNC Machining has the following significant advantages:

High precision: CNC machine tools are controlled by computer programs and can achieve very high machining accuracy. The movement of the machine and the path of the tool are precisely calculated and controlled by the computer, reducing human error and deviation.

High efficiency: CNC machine tools can be processed for a long time and continuously, and the processing is highly automated, reducing manual intervention and operation time.

Complex shape processing: CNC machine tools can process complex shapes and surfaces that are difficult to process with traditional machine tools. The machine can perform a variety of complex cutting and milling operations to achieve the machining of complex parts.

Repeatability: It can be used repeatedly to process the same parts, ensuring consistency and repeatability of the processing.

CNC machining has become an indispensable part of modern manufacturing.

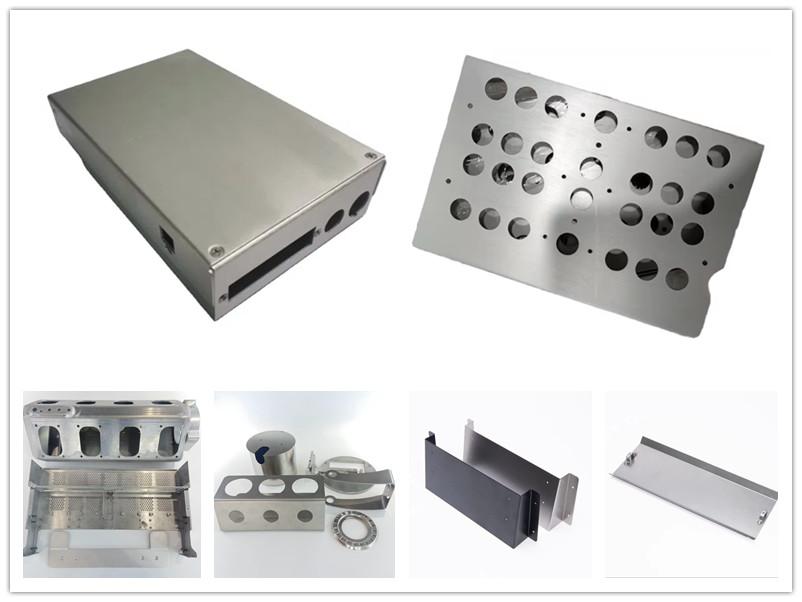

PRODUCT DISPLAY

|

|

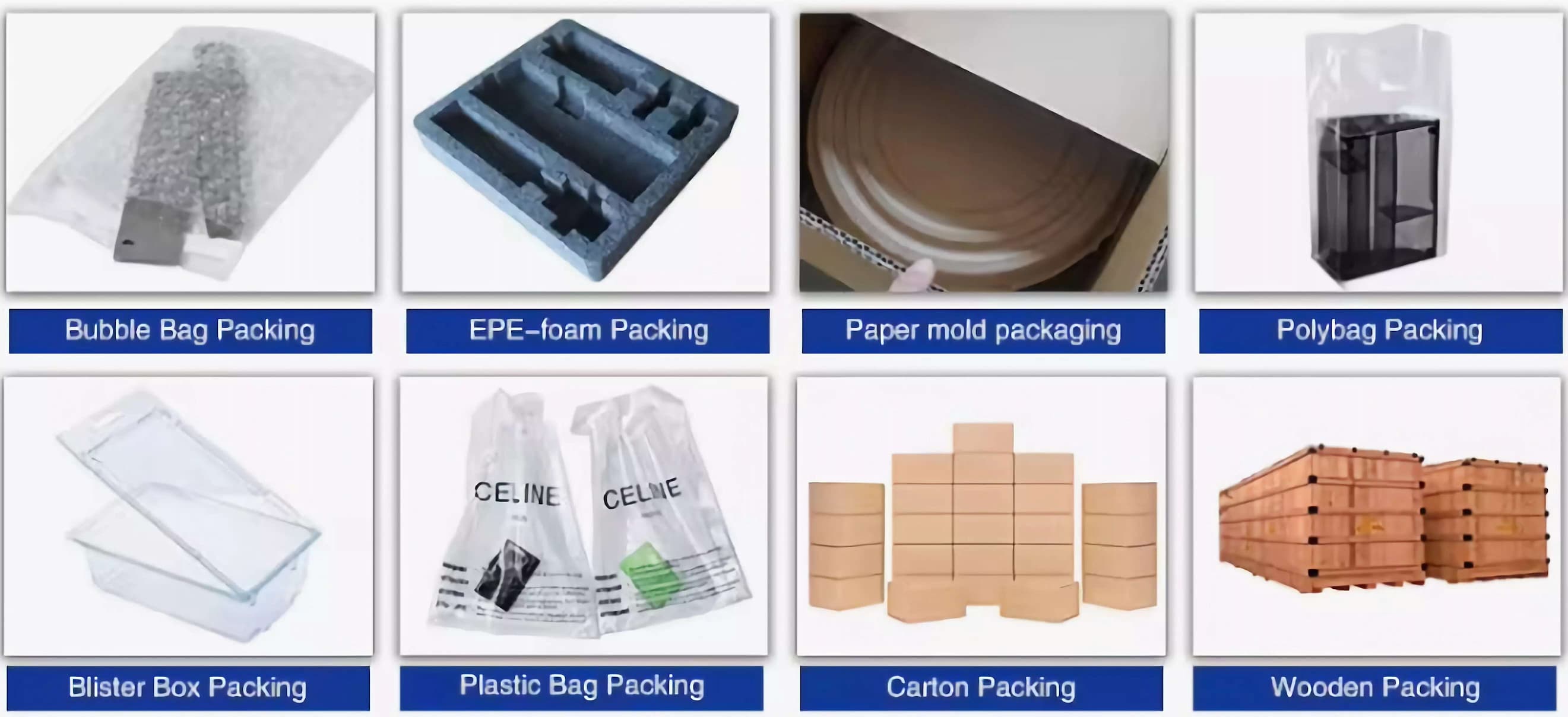

TRANSPORTATION AND PACKAGING OF CNC CUSTOM MACHINING PRODUCTS

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ:

Q: How do I get a quotation?

A: Please send us detailed drawings of the metal parts you need in formats such as DXF, DWG, or STEP. Along with these, include any specific requirements or special instructions you may have, and we will provide you with an accurate quotation based on this information.

Q: What if I don't have a drawing?

A: We can provide samples and create drawings for you. Our engineers will collaborate with you to design the appropriate drawings based on your requirements and ensure the confidentiality and safety of your design information.

Q: What is your production lead time?

A: Our standard production lead time is typically 1-4 weeks from order confirmation to completion. For more complex or bulk orders, the lead time may be extended, but we will inform you of this in advance.

Q: How do you ship goods? What about the packaging details?

A: For smaller quantities, we generally use courier services such as DHL, FedEx, or UPS. For larger quantities, we can arrange for air or sea freight. We offer standard packaging, but we are also willing to accommodate any special packaging requirements you may have.

Q: Do you provide samples? Is there a charge for them?

A: Yes, we can supply samples for a nominal fee. This helps us ensure the quality of the samples and that they meet your specific requirements.

Q: How do you guarantee product quality?

A: We have a stringent quality control system in place, with thorough inspections at every stage, from the sourcing of raw materials to the dispatch of finished products. Additionally, all our products are subject to precise machining and stringent testing to ensure they adhere to the highest quality standards.

Q: Can you handle special materials or complex shapes in sheet metal processing?

A: Absolutely, we have extensive experience in working with a variety of special materials and complex shapes. Whether it's stainless steel, aluminum, copper, or other alloys, we can provide customized sheet metal processing services tailored to your needs.