Outdoor construction waste disposal box with self-unloading function

Item No :

ZT-81078Order(MOQ) :

1 SetDesign :

ProvideRange of Application :

Construction works, Manufacturing Plant, Energy & Mining, FarmsMain Materials :

Carbon SteelCondition :

NewOutdoor construction waste disposal crane bin with self-unloading function

Quick Details:

| Raw Material | Carbon Steel or Custom |

| Application | Waste Treatment, Waste Management Recycling Bin |

| Feature | High Work Efficiency, Self-unloading Function |

| Color | Customized |

| Size | Customized |

| Thickness | 3-6 mm |

| Surface | Paint Spraying |

| Service Life | 10-20 Years |

| Key Words | Crane Bin, Skip Bin, Front Load Bin, Hook Lift Bin, Self-Tipping Bin, Dumping Hopper |

| Machinery Test Report | Provided |

| Video Outgoing-inspection | Provided |

Outdoor construction waste crane bins are large-capacity, durable trash containers specifically designed for outdoor construction environments to collect and manage various types of waste generated during the construction process. These bins are primarily used in construction sites, road works, and other outdoor operational areas to gather concrete blocks, bricks, stones, wood, metal waste, plastic packaging, and other construction debris.

Features and Benefits of Waste Management Recycling Bin:

1. Large Capacity Design: To meet the demand for collecting a substantial amount of waste from construction sites, these bins are typically designed with a large capacity, allowing them to hold a significant amount of garbage and reduce the frequency of emptying.

2. Durability: Constructed with high-strength materials, these bins are designed to withstand heavy loads and harsh conditions. They are resistant to leaks and are specially engineered to prevent heavy waste from contaminating the ground and soil, protecting against adverse weather conditions such as wind and rain.

3. Bottom Self-Dumping Design: To enhance cleaning efficiency, these bins feature a bottom self-dumping mechanism that allows for easy and quick emptying with the push of a button, reducing labor costs.

4. Mobility: For ease of transportation and relocation, some bins come equipped with wheels or lifting fixtures, facilitating movement within the construction site or transportation to waste disposal facilities.

PRODUCT DETAILS

| Material | Mild steel-Q235, Grade 250(AUS), A283(USA)/ Q345, Grade350 (AUS), A210(USA). |

| Size Range | Size from 10 to 80m yd. And customized size is also available. |

| Thickness of plates | 10 gauge 8 gauge (3 mm-4 mm) M/S plate for sides and 8 gauge 6 gauge(4 mm-5 mm) M/S for floor. Thicker plates are available to customer requirements. |

| Other specifications | 1). RHS are used for top rails, and top edge of plate continuous welded to RHS. 2). Fully and partly welded inside and outside. 3).Hook bar: Dia 50 mm. 4). Bottom chassis : PFC or 'I' beam, usually 200*75 PFC. 5). Curved sides are available. 6). Hinge and rollers-with grease points. |

| Options | 1) Two opening door. 2) Up opening door. 3) HDG (Hot dipped galvanizing. 4) Crane eyes on top. 5) Double door. 6) Ladder in front or in the back |

| Painting | Two times of primer & top coat. Primer : zinc-based epoxy (Grey);Top coat : Urethane (Customized). |

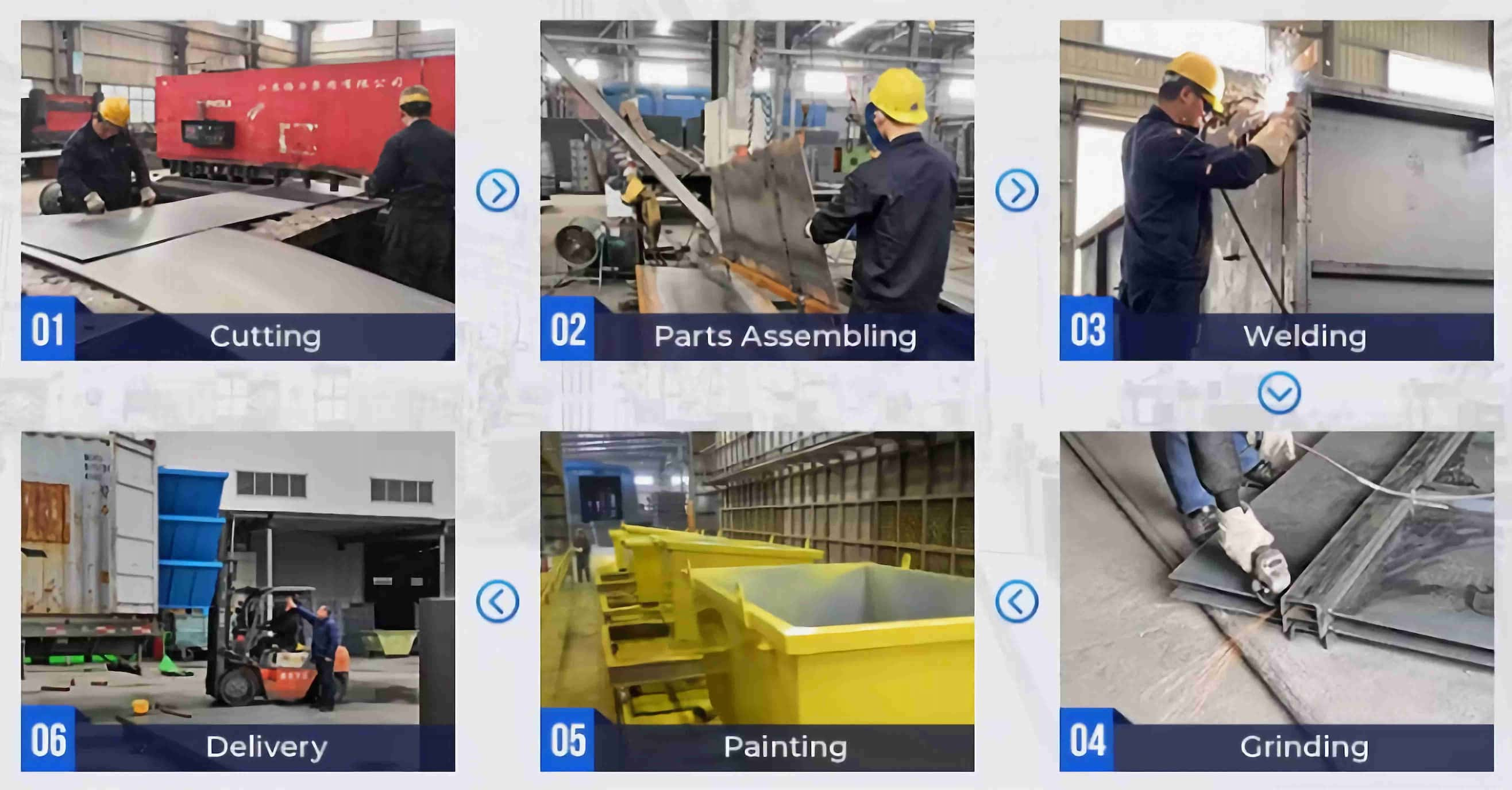

Manufacturing Process

Packaging and Transportation

|

|

Product Recommendation for Waste and Recycle Bin

FAQ:

1.Q: What is your delivery time of Waste Management Bin Replacement?

A: Seven days at the earliest. Usually within 15 days. It also depends on the number of orders and skip bin design.

2.Q: What are the terms of payment of commercial skip bin?

A: Payment method: 30% deposit at the time of PI signing, balance by telegraphic transfer before delivery.

3.Q: Do you have any samples of hook skip bin?

A: Yes, we provide samples at any time. We have charged some sample fees, which will be refunded for the next order.

4.Q: Can you produce according to the customer's design of hook skip bin?

A: Of course. We have a lot of experience in customizing waste bin.