Screw conveyors are widely used in various industrial fields, primarily for conveying powdery, granular, and small block materials. Based on different classification methods, screw conveyors can be divided into the following types:

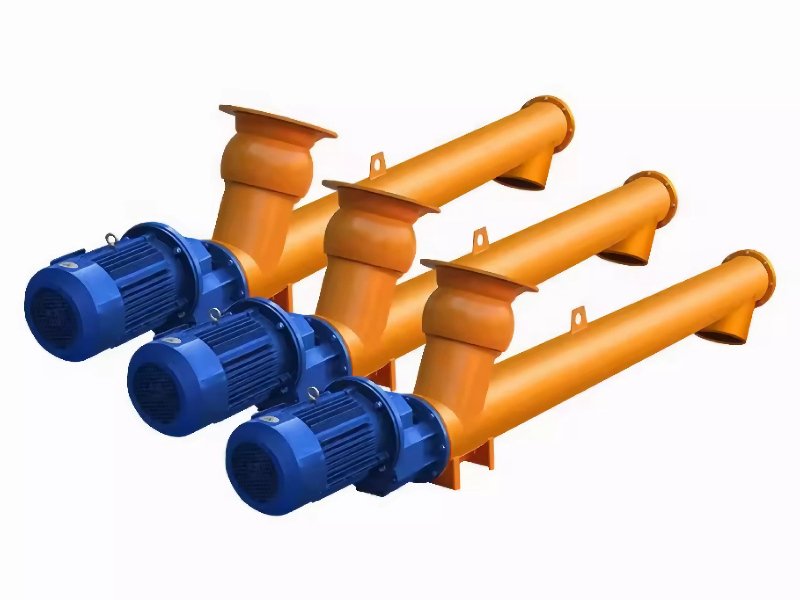

1. By Direction of Conveyance: They can be categorized into horizontal screw conveyors and vertical screw conveyors. Horizontal screw conveyors are mainly used for the horizontal movement of materials, while vertical screw conveyors are used for the vertical lifting of materials. Depending on specific application requirements, users can also combine screw conveyors of different directions for use, which greatly facilitates the conveyance of materials in work.

2. By Structural Features: This includes shafted screw conveyors and shaftless screw conveyors. Shafted screw conveyors consist of a screw shaft and a U-shaped trough, suitable for conveying various materials such as cement, grain, sand, and fly ash. These types of logistics mainly involve solid particles or powders, which are less likely to adhere to the blades or block the rotation of the blades during the conveying process, causing blockages in the screw conveyor. Shaftless screw conveyors, on the other hand, do not have a central shaft and are suitable for conveying viscous materials that might clog traditional shafted conveyors.

3. By Application Context: Examples include specialized screw conveyors for freezing, cooling, proofing, and water cooling. These devices have been improved and optimized for specific environmental needs. Typically, these types of screw conveyors require special customization of materials, conveying power, and length.

4. By Function: Examples include lifting screw conveyors, buffering and stacking screw conveyors, and spiral tube conveyors, each with different functions and application scenarios. Similarly, depending on the specific task, these three types of functional screw conveyors can also be customized or used in combination. Lifting screw conveyors and spiral tube conveyors are more common and widely used in various industrial production fields, especially in the construction engineering field and production processing links.

5. Special Design Screw Conveyors: Such as high-incline angle screw conveyors, heat exchanger screw conveyors, new type cooling screw conveyors, compound conveying units, variable pitch conveying units, and variable diameter conveying units. These specially designed screw conveyors can meet specific needs in practical engineering applications.

6. By Material: For instance, screw conveyors made of high-strength plastic are suitable for conveying food-grade materials. Additionally, the material selection for screw conveyors can also include stainless steel and carbon steel.

7. Flexible Screw Conveyors: The spiral body's central shaft is flexible and can be arranged according to spatial curves, suitable for both horizontal and vertical conveying of materials.

|

|