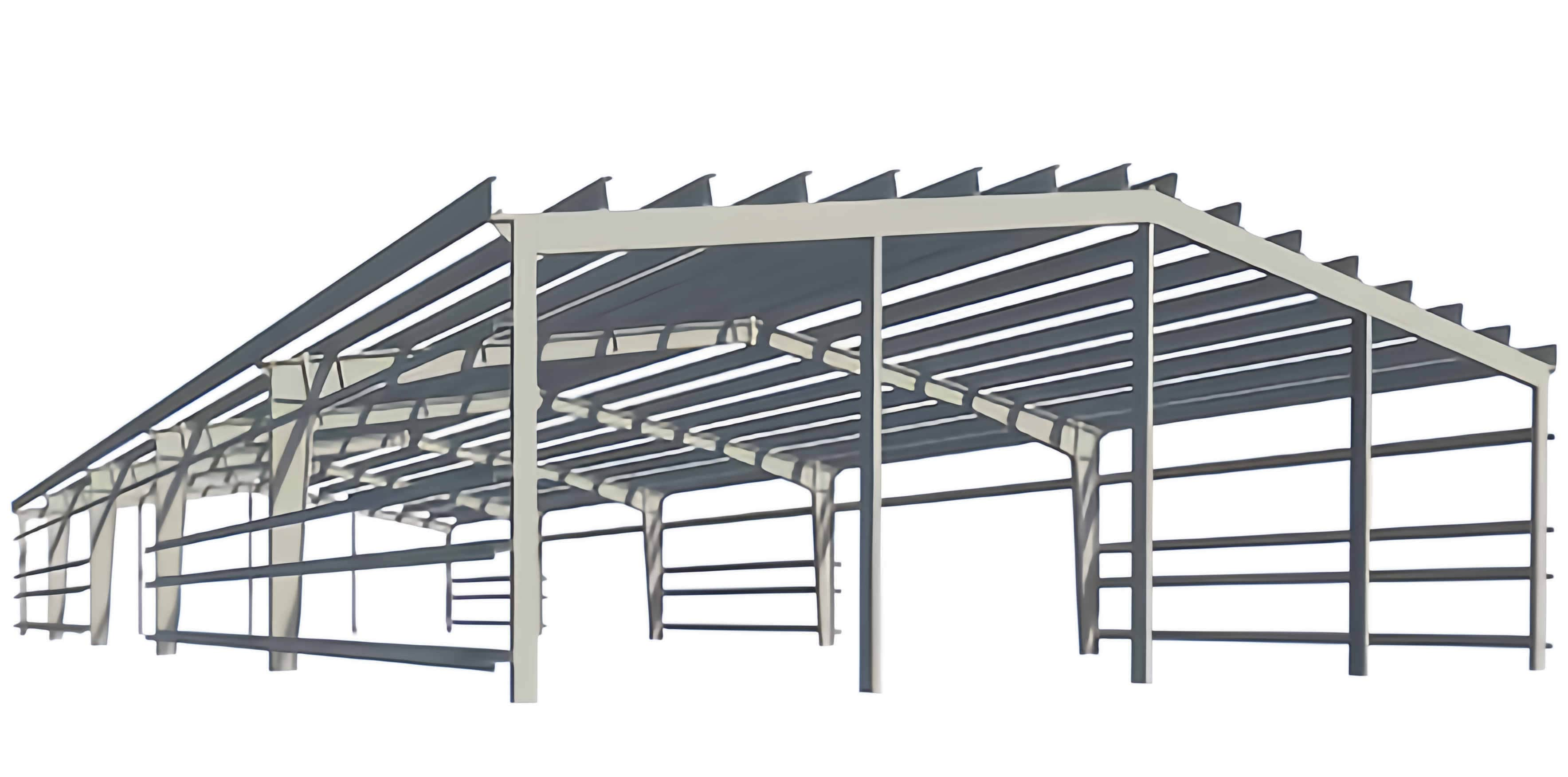

In the area of steel structure construction, the excellence of connections is paramount. A solid connection not only upholds the prefabricated steel frame structure building's strength but also boosts its safety and lifespan. We'll discuss the reasons behind these problems, their potential impacts, and offer smart solutions.

Uniform Tightening: The Key to a Seamless Fit

Before you get your hands dirty with installation, it's vital to iron out any kinks in the components to keep them in line. For a uniform tightening process, start from the heart of the connection and work your way out symmetrically. Plus, wielding the right tools for the job is a must to dodge over-tightening and uneven force. For example two beams are linked by a steel structure. Uneven bolt tightening could spell disaster for load-bearing, shaking the very foundation of stability. By hammering home the need for uniform tightening, we dodge a bullet of structural jeopardy.

Torque Values: Precision for High-Strength Bolts

When you're in the business of high-strength bolts, nailing the right torque is non-negotiable for airtight connections. A sloppy paint job or a smudge could be a deal-breaker. Let's get real about torque: in a steel structure where high-strength bolts are the glue between a column and a beam, over-torqueing could lead to stress overload, courting disaster like bolt breakage or a catastrophic collapse. So, let's drive home the point—sticking to torque specs is your safety net against such perils.